Mobile slaughter unit to improve animal welfare and strengthen short supply chains

What was the challenge/ problem addressed?

The operational group ‘Mobile Slaughter Unit’ (MSU) arose from the observation that small-scale (organic) livestock farmers who have slaughtered for direct sales have long had a problem finding an (organic-certified) slaughterhouse at an accessible distance. Smaller slaughterhouses have closed and larger slaughterhouses are often not equipped to slaughter a smaller number of animals. The long distances that have to be covered with the animals are a sticking point for many farmers and consumers. The final meat quality is also negatively affected by the animals’ stress associated with transport.

The operational group initially analyzed the available knowledge about mobile slaughter based on a literature study and drew up a list of questions and action points.

The company “Steunpunt Korte Keten” (“Consultancy for the Short Food Supply Chain”) conducted a survey among livestock farmers about their interest in mobile slaughter, their expectations, and needs. The typical demand is to slaughter 1 or 2 bovine animals at a time. For poultry, the total demand surveyed is about 35.000 animals per year.

Odisee University College studied the added value of mobile slaughter in terms of animal welfare. The claim that the final meat quality is negatively affected by the animals’ stress associated with transport, was confirmed.

The feasibility in terms of food safety, waste processing, and environmental permits was evaluated in collaboration with FAVV, OVAM, and the Environment Department. Although legislation makes it hard to implement a MSU, it does not make it impossible.

Finally, the economical feasibility was estimated. A MSU for poultry seems to be viable if about 300 animals are slaughtered at a time.

However, for cattle, a minimum of 6 to 7 animals should be slaughtered at a time to cover the operational costs. In the case fewer animals are slaughtered, the cost per animal quickly rises to unacceptable levels.

How did you solve the problem?

We found a solution for slaughtering small quantities of poultry on the farm. This makes it possible for small farmers to grow and commercialize a small number of poultry, special strains, or production methods that do not fit in industrial poultry production and processing. There is a small but clear market demand for this type of product and short food supply chains.

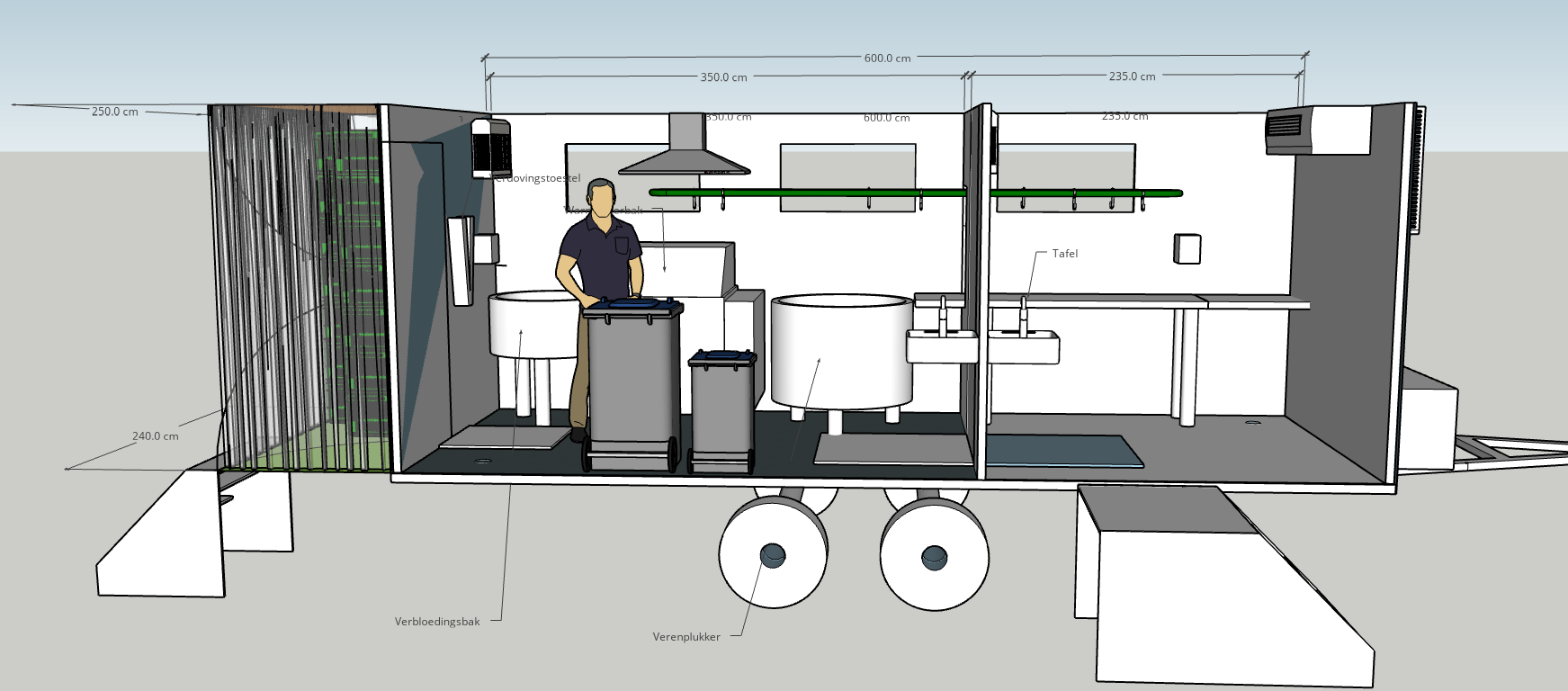

Based on the above results a MSU for poultry may seem the most feasible, both financially, technically, and within the regulatory framework. Therefore a technical and business plan has been developed by an investor and operator to put a MSU for poultry into practice in 2022 in Flanders.

For cattle, the typical demand by farmers to slaughter 1 or 2 animals at a time is far less than the minimally required quantity of 6 or 7 animals to cover the costs. This is confirmed by experiences of the Swedish company Hälsingestintan that operated a mobile slaughter unit for cattle in Sweden. Here too, economic feasibility is the biggest challenge. As a possible alternative, we now investigate the possibility of stunning and bleeding cattle on the farm before transporting the carcass to a nearby slaughterhouse for further processing. There are several examples of this technique in The Netherlands and Germany. The advantage of this technique is that the investment and operating costs are considerably lower than a fully mobile slaughter unit

What are the success factors in solving the problem?

Probably the most important success factor is that we worked together with several institutions, companies and people, all of them with their own expertise. The shared knowledge was vital to find solutions for this complex project

Unexpected fails, if any

The most difficult aspect is to meet the legal requirements. It took us very long to understand all legal requirements and to find solutions to comply with them.

Lessons learned

There are 3 main challenges to planning and implementing a small scale mobile slaughter unit for poultry:

- Technical

- Economical

- Legal (food safety, environment, and waste management)

The technical aspect seems to be the easiest. From a technical point of view, it is perfectly possible to slaughter poultry in a moble unit.

An economical model shows that a mobile slaughter unit is only competitive and profitable if the infrastructure is used sufficiently throughout the year and a minimum of animals are slaughtered per working day.

The most difficult aspect is to meet the legal requirements, which are mostly focused on large-scale and non-mobile slaughterhouses. Most legislation comes with a high cost, which makes it rather economically than technically difficult to comply with.

What role does the advisor or advisory service play within the practical case?

BioForum (coordination, food safety, and quality system, technical and economical aspects), together with researchers and advisors of Odisee University College (animal welfare), Steunpunt Korte Keten (legal aspects on food safety), Nature & Progrès Belgique (experiences in Wallonia) and Innovatiesteunpunt (marketing) all participated in this project, contributing and sharing the specialized knowledge of each.

Can your approach be transferred and/or adapted for other innovation challenges and regions?

Yes

Estimated transferability on a scale from 1 to 5

(where 1 is easy and 5 very difficult)

1

For sharing the experience on the good practice, please contact Paul Verbeke (paul.verbeke[at]bioforum.be)